Tailored Fiber Placement (TFP) Carbon Fiber

Using innovative tailored fiber placement (TFP) technology, we can produce carbon fiber components more rapidly and better optimize them for structural performance.

Innovative by Design

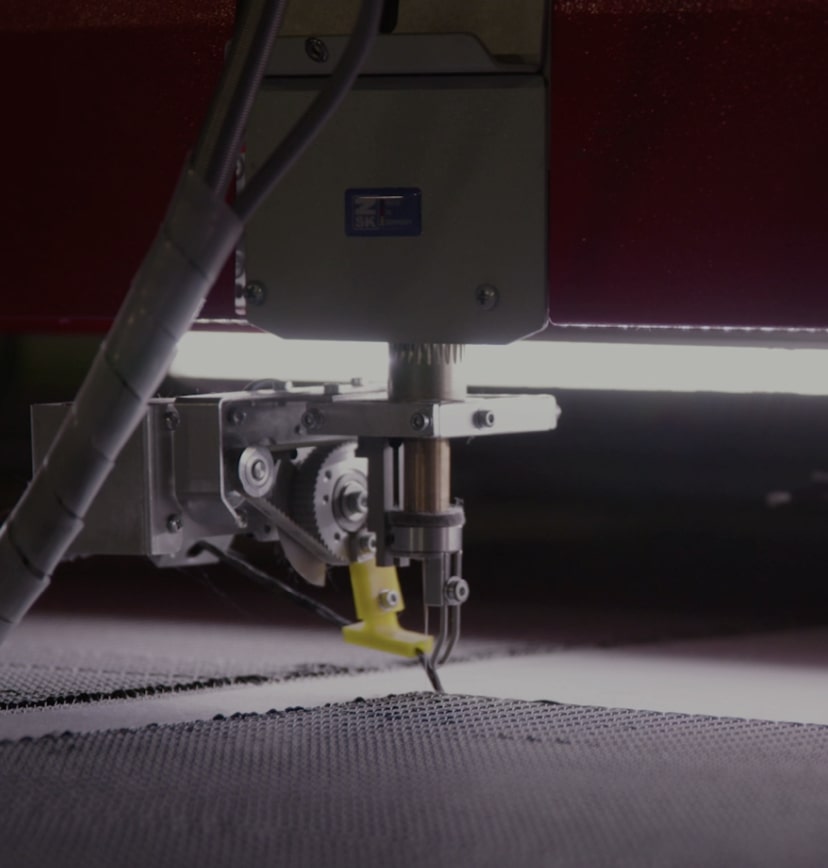

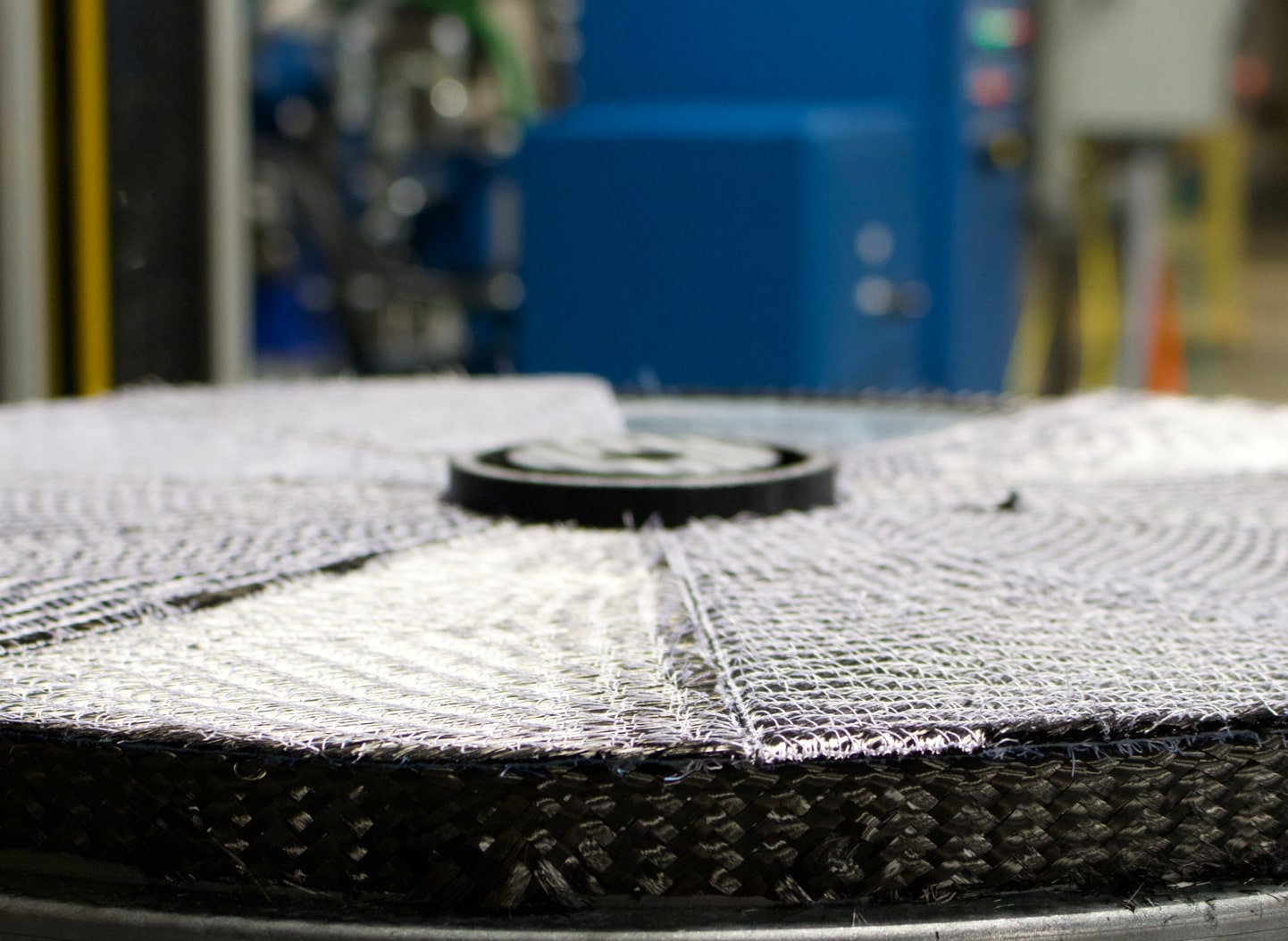

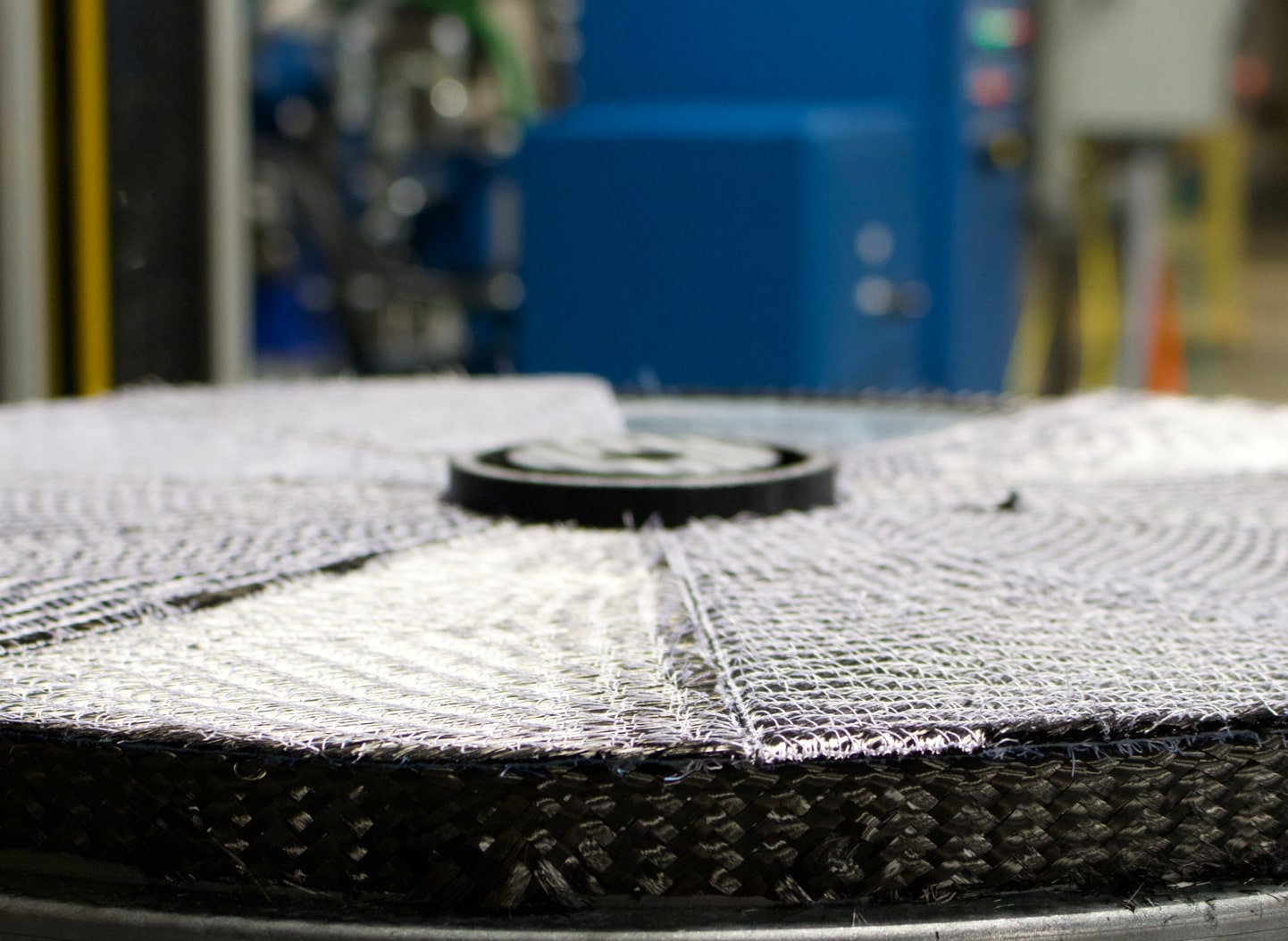

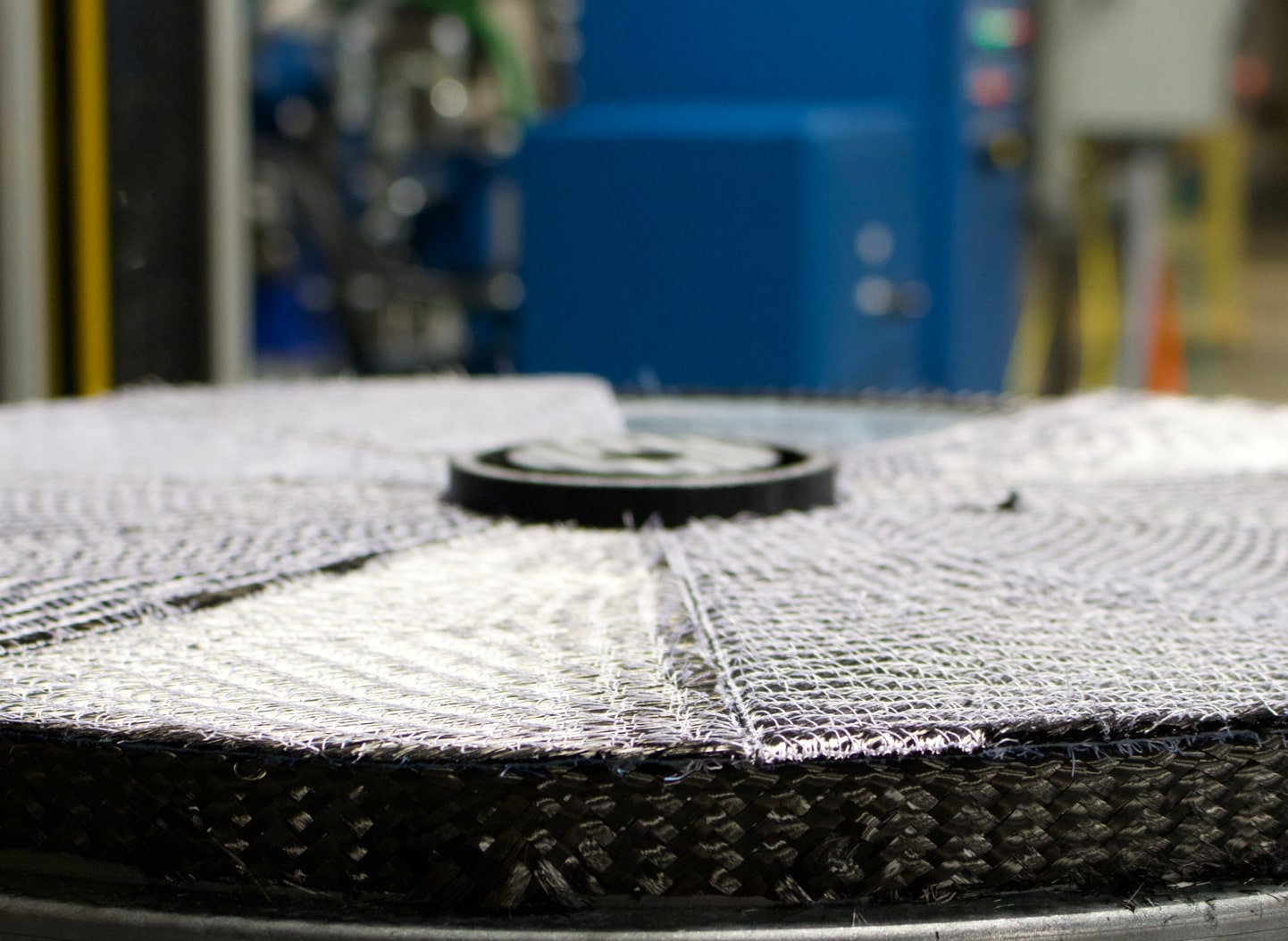

TFP machines enable the specific placement—or stitching—of carbon fibers onto a mold. Traditionally, carbon fiber components were created by cutting shapes out of carbon fiber sheeting. Using TFP, ESE is able to precisely place carbon fibers onto a base material, orienting the fibers in specific directions and patterns to optimize structural performance. This increases the strength and durability of ESE’s carbon fiber parts, allowing them to manage loads and stresses more effectively.

Faster Layup & Less Waste

In addition to optimized design, TFP enables faster production and higher volume manufacturing of carbon fiber components and minimizes waste reduction. Since the implementation of TFP, ESE has been able to reduce layup time by as much as 50% while cutting material waste by 80%. The more complex the design is from a layup and engineering perspective, the more substantial the benefits that TFP will allow you to materialize.

Advantages of Carbon Fiber TFP

- Fiber orientation tailored at each ply

- Near net-shape plies

- Significantly reduced raw material waste

- Tow-to-part manufacturing

- Simplified, faster layups

Ready to start a project?

Get the ESE advantage

Stay Informed

Sign up to receive our updates and carbon fiber industry news